The three ICH guidelines which throw light upon quality-by-design and related aspects include Q8 Pharmaceutical development, Q9 Pharmaceutical risk management and Q10 Pharmaceutical Quality systems. All the major objectives with regard to quality issues are being addressed by the ICH guidelines. After that, ICH (International Conference on Harmonization) discussions in July 2003 (Brussels) agreed a consensus vision to develop a harmonized pharmaceutical quality system applicable across the life cycle of the product emphasizing an integrated approach to risk management and science. The initiation of the cGMPs for the 21st Century and the publication of the Process Analytical Technology (PAT) guidance in 2004 by the FDA gave the way for the modernization of the pharmaceutical industry. In the area of pharmaceutical quality Food and drug administration (FDA) announced proposed amendments to "Current Good Manufacturing Practices" (cGMP) in 2002, with an emphasis on establishing a 21st century outlook on pharmaceutical manufacturing in order to establish a more systematic science and risk based approach to the development of pharmaceutical products.

QbD requires identification of all critical formulation attributes and process parameters as well as determining the extent to which any variation can impact the quality of the finished product. As a result, a quality issue can be efficiently analyzed and its root cause quickly identified. Instead of relying on finished product testing alone, QbD provides insights upstream throughout the development process. Regulatory bodies are therefore focusing on implementing quality by design (QbD), a science based approach that improves process understanding by reducing process variation and the enabling process-control strategies. In traditional, the product quality and performance are predominantly ensured by end product testing, with limited understanding of the process and critical process parameters. However, drug recalls, manufacturing failure cost, scale up issues and regulatory burden in recent past produce huge challenge for industry. Pharmaceutical industry is constantly searching the ways to ensure and enhance product safety, quality and efficacy.

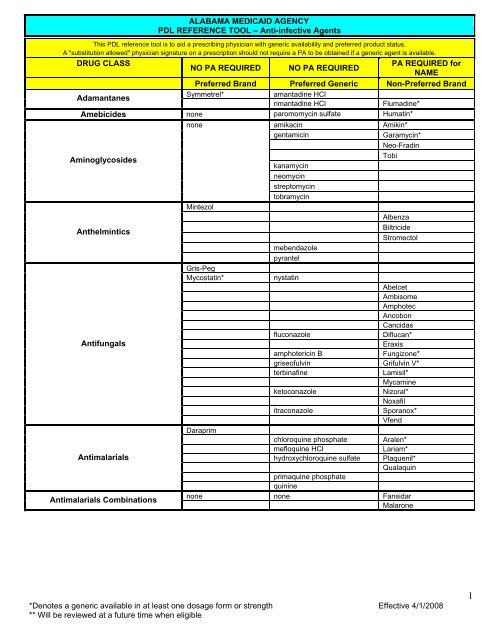

#Drug reference tool how to

How to cite this article: Gandhi A, Roy C Quality by Design (QbD) in Pharmaceutical Industry: Tools, Perspectives and Challenges PharmaTutor 2016 4(11) 12-20 Some of the QbD elements include defining target product quality profile, designing product and manufacturing processes, identifying critical quality attributes, process parameters, and sources of variability & controlling manufacturing processes to produce consistent quality over time The purpose of this article is to discuss the concept of pharmaceutical Quality by Design and describe how it can be help to ensure pharmaceutical quality & drug development. It mainly covers designing and developing formulations and manufacturing processes to ensure predefined product quality. It serves as a bridge between industry and drug regulatory authorities to move towards a scientific, risk based, holistic and proactive approach for development of pharmaceutical product.

Ltd., Fatwah, India.Ģ Department of pharmaceutics, Gupta College of Technological Sciences, West the concept of “Quality by Design” (QbD) gaining much attention among pharmaceutical industries for maintaining Quality. 1 Production cum Quality Manager, Kras Pharmaceuticals Pvt.

0 kommentar(er)

0 kommentar(er)